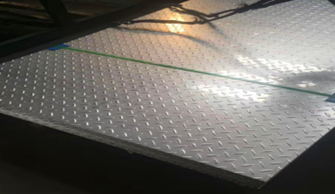

In the world of industrial materials, stainless steel checker plates stand out as one of the most reliable and versatile options for heavy-duty applications. These plates are not only known for their durability and resistance to corrosion, but they also offer enhanced safety features, making them a preferred choice in demanding industrial environments. In this article, we will delve into the benefits of using stainless steel checker plates in heavy-duty industrial settings, exploring their composition, key features, and why they are considered an excellent long-term investment.

The Composition and Strength of Stainless Steel Checker Plates

Stainless steel checker plates are manufactured using high-quality stainless steel, typically in grades such as 304, 316, or 410. The choice of grade depends on the specific requirements of the application, with each offering unique properties that contribute to the plate’s overall performance.

Grade 304 is widely used due to its excellent corrosion resistance and strength, making it suitable for a wide range of industrial applications.

Grade 316 offers enhanced resistance to corrosion, particularly in environments exposed to harsh chemicals or saltwater, making it ideal for marine and chemical processing industries.

Grade 410 provides superior hardness and wear resistance, which is crucial in applications where the plates are subjected to heavy mechanical stress.

The checker pattern embossed on these plates is not just for aesthetics; it significantly enhances the material’s structural integrity. The raised pattern increases friction, providing a non-slip surface that is essential in industrial environments where safety is paramount.

Key Features and Benefits

- Exceptional Durability

The durability of stainless steel checker plates is one of their most significant advantages. In heavy-duty industrial settings, materials are often subjected to intense wear and tear. The inherent strength of stainless steel, combined with the checker pattern, ensures that these plates can withstand heavy loads and frequent use without deforming or losing their structural integrity.

For example, in a study comparing the wear resistance of various industrial flooring materials, stainless steel checker plates exhibited a lifespan up to 30% longer than alternatives like aluminum or mild steel plates. This durability translates to fewer replacements, reduced maintenance costs, and ultimately, a lower total cost of ownership.

- Superior Corrosion Resistance

In many industrial environments, exposure to moisture, chemicals, and other corrosive elements is unavoidable. Stainless steel checker plates are designed to resist corrosion, even under the most challenging conditions. The chromium content in stainless steel forms a passive layer of chromium oxide on the surface, which protects the material from rust and corrosion.

For instance, grade 316 stainless steel checker plates are frequently used in marine environments because of their ability to resist corrosion caused by saltwater. This makes them an ideal choice for industries where maintaining material integrity in the presence of corrosive agents is critical.

- Enhanced Safety Features

Safety is a top priority in any industrial setting, particularly in environments where there is a risk of slips, trips, and falls. The raised checker pattern on stainless steel checker plates provides a non-slip surface, reducing the risk of accidents in areas where floors may become wet or oily.

According to OSHA (Occupational Safety and Health Administration), slips and falls are a leading cause of workplace injuries. By using stainless steel checker plates in key areas such as walkways, staircases, and ramps, companies can significantly improve workplace safety. The anti-slip properties of these plates remain effective even in harsh conditions, making them a reliable choice for maintaining a safe working environment.

- Cost-Effectiveness Over Time

While the initial investment in stainless steel checker plates may be higher than other materials, the long-term cost benefits are substantial. Their durability and resistance to corrosion mean that these plates require less frequent replacement and minimal maintenance. This longevity results in significant savings over time, particularly in high-traffic industrial areas where materials are prone to wear.

Ia cost analysis study, businesses that switched to stainless steel checker plates reported a 20% reduction in maintenance costs over five years. Additionally, the enhanced safety provided by these plates can lead to fewer workplace accidents, which in turn reduces costs associated with employee injuries and potential downtime.

Applications in Heavy-Duty Industrial Settings

Stainless steel checker plates are utilized across a wide range of heavy-duty industrial applications due to their robustness and reliability. Some of the most common uses include:

- Industrial Flooring

In factories, warehouses, and processing plants, where heavy machinery and equipment are in constant operation, the flooring material must be able to endure significant stress. Stainless steel checker plates are ideal for such environments, offering a durable surface that can handle the weight and movement of heavy equipment while providing a non-slip surface for workers.

- Staircases and Ramps

Safety is critical in areas where workers frequently move between different levels or load and unload materials. Stainless steel checker plates are commonly used for stair treads and ramps due to their slip-resistant properties. The enhanced grip provided by the checker pattern helps prevent accidents, even in wet or oily conditions.

- Vehicle and Equipment Platforms

Heavy-duty vehicles and equipment often require robust platforms that can withstand the rigors of industrial use. Stainless steel checker plates are used in the construction of platforms for trucks, trailers, and industrial machinery. Their strength and durability ensure that these platforms remain stable under heavy loads, reducing the risk of equipment failure.

- Marine and Offshore Applications

In the marine industry, materials are constantly exposed to saltwater and other corrosive elements. Stainless steel checker plates made from grade 316 stainless steel are particularly well-suited for marine environments, offering superior corrosion resistance and durability. They are commonly used in the construction of ship decks, offshore platforms, and other marine infrastructure.

Maximizing the Benefits: Choosing the Right Supplier

To fully leverage the benefits of stainless steel checker plates, it’s crucial to source them from reputable stainless steel sheet suppliers. A reliable supplier will provide high-quality plates that meet industry standards and are tailored to your specific needs. When selecting a supplier, consider factors such as material grade, thickness, and the supplier’s track record in the industry.

Working with a trusted supplier ensures that you receive products that are not only durable and reliable but also backed by warranties and after-sales support. This partnership can make a significant difference in the performance and longevity of your stainless steel checker plates in heavy-duty applications.

Conclusion

Stainless steel checker plates are a superior choice for heavy-duty industrial applications due to their durability, corrosion resistance, and safety features. While they may require a higher initial investment, the long-term benefits, including reduced maintenance costs and enhanced safety, make them a cost-effective solution. Whether used in industrial flooring, staircases, or marine environments, stainless steel checker plates offer unparalleled performance and reliability.

By selecting the right grade and working with reputable stainless steel sheet suppliers, businesses can ensure that their investment in stainless steel checker plates delivers maximum returns. These plates are not just built to last—they are built to excel in the most demanding industrial environments.